AR - GE

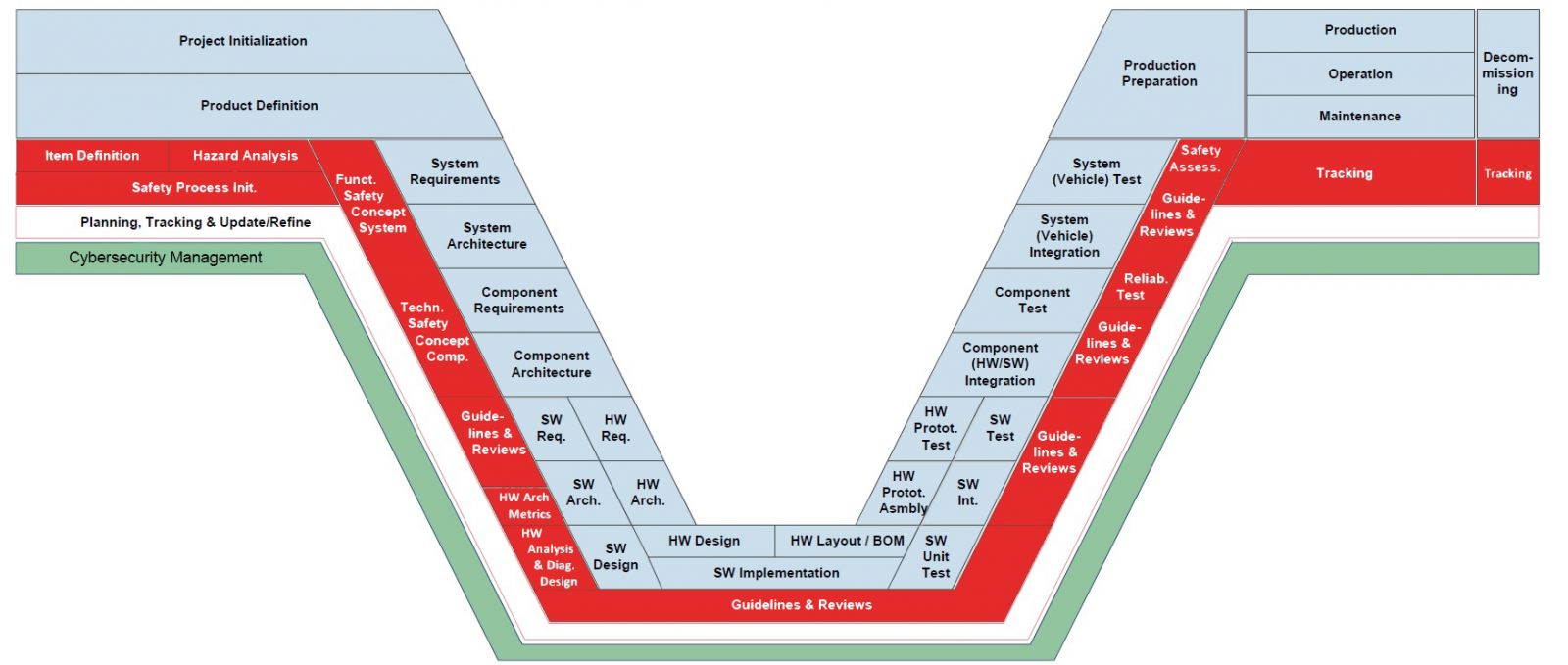

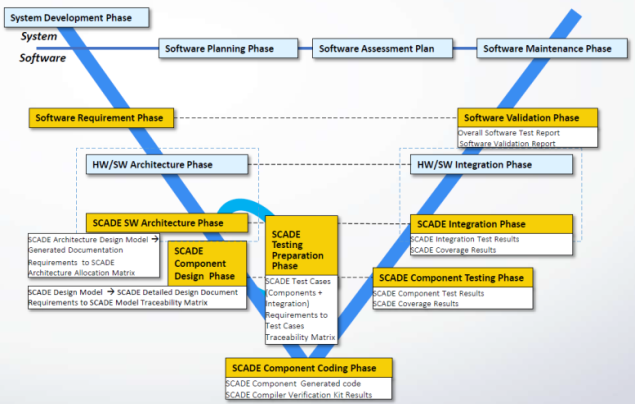

The designs of new products at Seger are carried out together with APQP team formed with the participation of different departments under the leadership of the R&D team. New product studies are supported at necessary stages by design methods such as DOE, QFD, Design FMEA, Process FMEA, Software FMEA, Benchmark, Finite Element Analysis for Mechanical & Acoustical Simulations. In the workshop where the prototype products used by the R&D team are produced, the 3D rapid prototyping machine, which can produce prototypes of plastic parts, accelerates the business processes and prevents material waste at the same time. Prototype products produced are tested by our R&D team in performance tests in the Quality Laboratory in order to meet the harshest engineering conditions. Hardware and Software designs made by our Electronic R&D are made according to V Cycle. Our electronic products can be designed and developed to meet Automotive Requirements for ISO 26262 Functional Safety and ISO 21434 Cyber Security.

With the approval of the new product design, the necessary process design studies are carried out in order to produce the product in the most efficient and highest quality way. Horn assembly lines, workstations, assembly and control fixtures, all kinds of plastic and metal molds in our factories in China and Bursa were designed, produced and put into operation by our experienced and expert teams. In new process designs, we make use of high-tech automation systems while prioritizing error-free and Poka-Yoke studies. As a reflection of our passion for excellence, our quality team holds production analysis meetings every day and evaluates the analysis of the problems experienced in all our production lines on a shift basis. Our R&D team works in partnership with all departments to minimize problems and scraps. In addition, the information obtained through customer feedback sheds light on the development of our products and processes, and directs the R&D department in new product and process designs.

Engineering Programs and Equipment that we use

© 2024 All rights reserved, SEGER